Great progress has been made in the research and development of thermal boiler detection robot of Shihe Technology

- Categories:News Center

- Author:

- Origin:

- Time of issue:2020-01-10 09:36

- Views:

(Summary description)Great progress has been made in the research and development of thermal boiler detection robot of Shihe Technology

Great progress has been made in the research and development of thermal boiler detection robot of Shihe Technology

(Summary description)Great progress has been made in the research and development of thermal boiler detection robot of Shihe Technology

- Categories:News Center

- Author:

- Origin:

- Time of issue:2020-01-10 09:36

- Views:

According to statistics, the global annual industrial maintenance cost for infrastructure and key equipment is more than 100 billion US dollars. China's power plants invest 100 billion yuan for inspection and maintenance every year. The inspection and maintenance cycle of Chinese electric boilers is generally 1-3 weeks, and the inspection and maintenance process is very dangerous. In the detection of boiler water wall, chemical tank and other equipment, the traditional manual detection method is inefficient,and easy to cause missed detection, false detection and other phenomena, resulting in the risk of equipment failure.

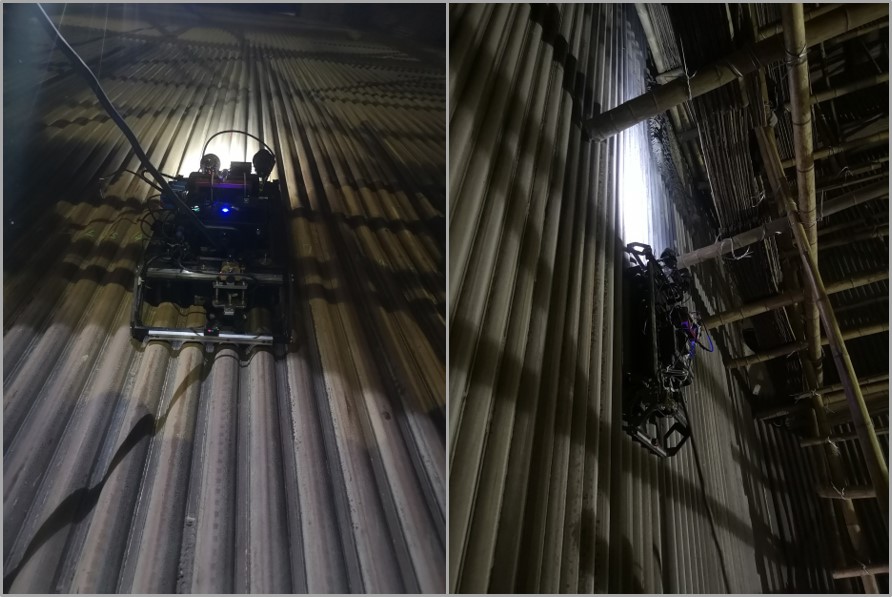

After a year of independent research and development, Shihe thermal power boiler detection robot lt-td-02 was successfully launched. The robot can realize automatic detection, remote monitoring and automatic data storage of water wall of thermal power boiler, and replace workers from dangerous work. Lt-td-02 adopts lightweight and modular design, which can quickly realize the automatic detection of water wall thickness, with the detection accuracy of 0.01mm, and realize the visualization of detection data. At present, the product has been tested and verified in large scale in Maanshan Iron and steel plant, Shijiazhuang Liangcun power plant, Baotou Aluminum Thermal Power Plant and other places, and the test effect has been affirmed by power plant customers.

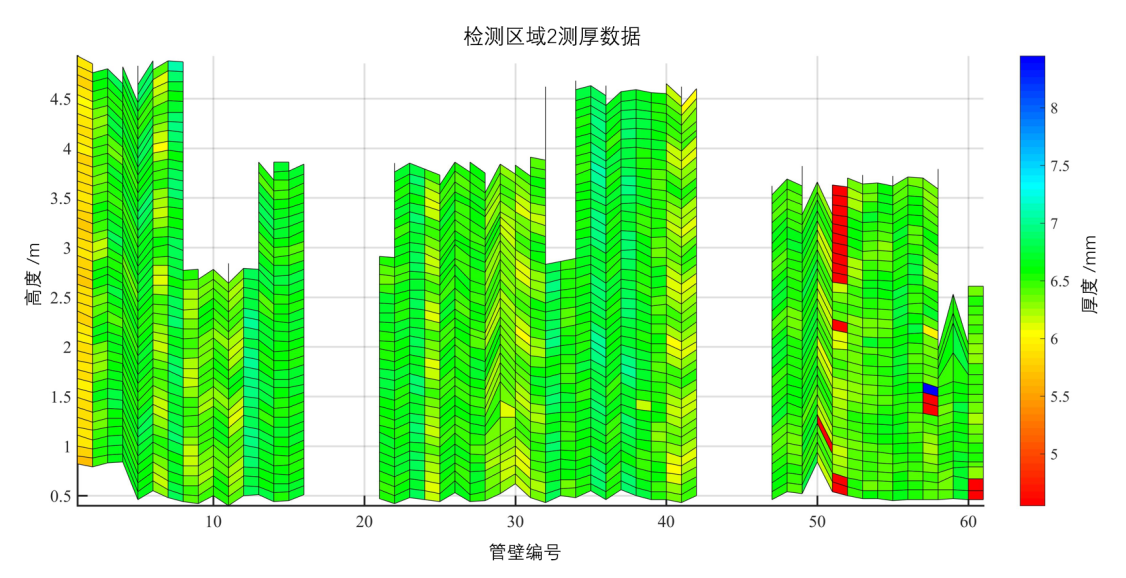

In September 2019, lt-td-02 thermal boiler detection robot carried out continuous operation test in Maanshan Iron and steel plant's own power plant, and obtained a large number of detection data. Through the analysis of the test data, an intuitive visual analysis report is formed, through which the staff can easily complete the treatment of furnace problems.

According to the detection needs of different customers, Shihe technology has also developed two other detection robots for different use scenarios: thermal fast detection robot and thermal composite operation robot.

The thermal power quick inspection robot is smaller and lighter, which can be carried and operated by one person. The robot can be widely used in power plant self inspection or emergency detection, and it is the right assistant for temporary maintenance or emergency repair.

The thermal power composite operation robot is an all-around detection robot. The integrated driving mode endows the robot with super strong motion elements, which enables the robot to walk and turn freely on the water-cooled wall, and can turn over the flame angle. Powerful power platform and rich interfaces can carry a variety of functional unit components. The robot can realize the functions of furnace dust removal, wall thickness detection, thinning detection, feature marking and data analysis.

With the thermal boiler detection robot, the detection accuracy is 0.01mm, and the detection efficiency is greatly improved. According to our test in a power plant in Shandong Province, 687 40 m high boiler water wall tubes were tested by three thermal power quick inspection robots, and the operation time was only 10 hours. The same test task, using manual operation, requires 8 people, takes 24 hours to complete. The comprehensive operation efficiency is increased by 5-7 times, and the cost is reduced by more than 50%. " Wang Zhichao, CTO of Shihe technology, said, "the most important thing is that our robot can achieve massive data detection, while the detection results are visualized, defects are automatically marked, and the detection efficiency and quality are greatly improved."

At present, two products of Shihe technology thermal power quick inspection robot and thermal power composite operation robot have been completed prototype research and development, and are under centralized test in thermal power plants all over the country. It is expected to officially face the market by the middle of 2020.