Shihe science and technology successfully tested the boiler water wall detection robot

- Categories:News Center

- Author:

- Origin:

- Time of issue:2018-12-17 13:41

- Views:

(Summary description)Shihe technology thermal power boiler water wall detection robot experiment is successful.

Shihe science and technology successfully tested the boiler water wall detection robot

(Summary description)Shihe technology thermal power boiler water wall detection robot experiment is successful.

- Categories:News Center

- Author:

- Origin:

- Time of issue:2018-12-17 13:41

- Views:

Wear safety helmet, headlight, dust mask, work clothes, thickness gauge, safety belt, then take a bottle of mineral water, follow the fence, turn over and stand on the steel pipe "elevator" and slowly put yourself down The day's work of "Spider Man" for boiler water wall detection started like this.

Water wall testing workers are a kind of work that few people know. If they are not in the power industry, they may not know what water wall is. The water wall is the equipment in the thermoelectric boiler. It is a steel pipe arranged inside the boiler. The inside is flowing water, which takes the heat from the boiler furnace through the water and plays a cooling role. As the furnace is full of flames, with a height of several hundred degrees, the water wall often breaks and bursts. Cracking or pipe bursting will cause the temperature of flue gas in each section to drop, cause the boiler to put out the fire, alarm the leakage detection device of the boiler pipe, and abnormal static blade opening when the induced draft fan is put into automatic operation... Therefore, the detection of the water wall has become an important maintenance task in the thermal power industry.

The traditional way is to carry on the inspection by the way of the scaffold, use the thickness gauge to carefully measure the situation of each pipe, and use the marking pen to record the data on the side wall, so as to provide reliable reference data for the later maintenance personnel.

The traditional manual detection has several shortcomings:

First of all, the efficiency is low. People have to take a thickness gauge to test each pipe from top to bottom. It takes about 2 hours for each "Spider Man" to test from top to bottom, and it takes more than 1 hour for some complicated pipes to test the physical strength of "Spider Man". Generally, spider man works in the air for more than 8 hours a day.

Secondly, the rate of missed inspection is high. The same horizontal line of each tube needs to detect three data in the left, the middle and the right. Even if the upper and lower spacing is 5cm, there are still many places that have not been collected. And there are many pipes, so it's easy to see the eyelet. "Spider Man" detects half of them. If it finds any missing places, it needs to re detect them. Even so, in order to prevent missing inspection, three batches of people need to check the same scene three times to achieve the purpose of not missing.

Safety accidents are easy to occur. The boilers in the power plant are generally more than 30 meters long. On average, they work at heights for at least 8 hours every day. Ordinary people shiver when standing on them, let alone concentrate on their work. If they can't concentrate, they will have accidents. Secondly, the environment inside is very bad. There is flowing air in the furnace, which is airtight, and the temperature is about 50 degrees. Many people will feel sick, chest tightness, or even faint directly when they enter. So every year, there are many safety accidents, and the industry has been looking for a detection method that can replace spider man.

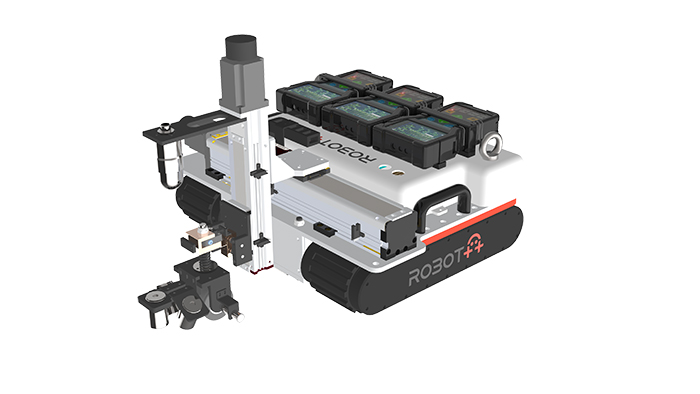

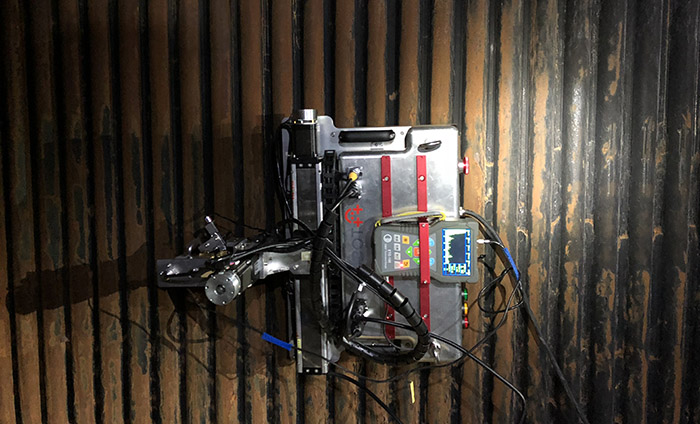

After half a year's research and development, Beijing Shihe technology has finally overcome many technical problems, such as vertical load climbing, data back, and successfully developed a boiler water wall detection robot. After many tests, the robot has the purpose of replacing manual detection.

On December 14, the company's technical team took the inspection robot to a power plant in Hebei Province for on-site test, and achieved success, which was fully affirmed by the leaders of the power plant and all the personnel present. The success of this test represents that Shihe technology has made a new breakthrough in water wall inspection technology, and successfully replaced the traditional manual inspection with robot, which solved this problem in the industry A long-standing problem.

The robot has the following advantages:

First of all, it can completely replace the manual high altitude detection. The robot can complete the whole detection task independently, only need people to carry out some logistics work in the early and later stage. In the process of operation, it does not need manual assistance and supervision, completely isolating the contact between people and the harsh environment.

Secondly, the data is more abundant and accurate. The robot can export all data according to the feedback frequency of the flaw detector signal. Compared with the manual sampling detection, it can detect the operation of the water wall more truly.

Maintenance cost is reduced. The traditional manual detection of a boiler's water wall usually takes about 10 days, two to three times. Robot detection will reduce the time and cost to 70%, only one detection is needed.

The chart shows that maintenance is easier. Compared with the manual recording on the pipe wall, the robot can export data to form an intelligent chart which can be stored, forewarned and analyzed. It will bring convenience to later detection and reduce misjudgment and omission.

Shihe technology has been committed to using aerial robots to replace the traditional spider man in high-risk operations, to solve the problems of safety, efficiency and cost in the traditional industry. At present, the company has developed ship derusting robot, water wall detection robot, tank spraying robot, wind power detection robot, cylinder detection robot, etc., which are all in the stage of industry promotion and application. In the future, Shihe technology will take the vision of "no dangerous work in the world", constantly break through innovation, and bring more intelligent and professional aerial work robots to the industry.