We use robots to dry ships for derusting and spraying

- Categories:News Center

- Author:

- Origin:

- Time of issue:2019-01-21 11:54

- Views:

(Summary description)Recently, the robot + + product group carried out a number of application tests in a shipyard in Jiangsu Province, including ship cleaning, derusting, spraying, etc., which were warmly welcomed and pr

We use robots to dry ships for derusting and spraying

(Summary description)Recently, the robot + + product group carried out a number of application tests in a shipyard in Jiangsu Province, including ship cleaning, derusting, spraying, etc., which were warmly welcomed and pr

- Categories:News Center

- Author:

- Origin:

- Time of issue:2019-01-21 11:54

- Views:

Recently, under the leadership of Zhou Weiping, deputy general manager of the company's market, the robot + + product team carried out a number of application tests in a shipyard in Jiangsu Province, including ship cleaning, rust removal, painting, etc., which were warmly welcomed and praised by customers. The relevant test results provide important data for the company's follow-up product improvement, as well as valuable experience for product process optimization and human-computer interaction improvement.

The corner of the great ship

With the gradual globalization of China's economy, shipping has become the main force of Global trade. After going out to sea for a period of time, the ship needs to be maintained later. Derusting and spraying are two main processes in ship maintenance.

For a long time, manual hand-held sand blasting gun and spray gun have been used for ship derusting and painting. Manual operation is flexible, but there are many disadvantages. First of all, there is a risk of falling when workers work with pneumatic sandblasting gun at high altitude, and the gravel is splashed at high speed, which is easy to hurt the operator, so it has a strong risk; secondly, the noise of sandblasting operation is as high as 100 decibels, which causes great damage to the operator's eardrum, while the VOC mist of spray painting spreads around the operator, which causes serious damage to the operator's lung. Such dirty and tired young people are more and more reluctant to participate, and the decrease of the number of labor forces the increase of the cost of employment year by year. At present, these disadvantages have prompted the shipbuilding industry to find new methods and new models. At this time, the emergence of robots, just from the technology and trend to meet the market demand. This time, the robot + + team went to the shipyard for several consecutive days of testing, which is exactly the result of a good match between the two sides.

Next, let's take a look at how high-tech robots work!

First of all, we have carried out the non operation test of the ship climbing robot. We have carried out repeated tests one by one on the reliable adsorption ability, surface adaptability, vertical load-bearing ability, inverted angle load-bearing ability, waterproof and sealing performance, moving speed and flexibility, and safety guarantee ability of the robot.

est of load capacity of inverted elevation angle

Surface adaptability test

Then, we test the robot operation test, including: single pipe water sand rust removal, double pipe water sand rust removal, ultra-high pressure pure water rust removal, and spray test.

Sand blasting and derusting of single pipe

Double pipe sand blasting and derusting operation

Derusting effect

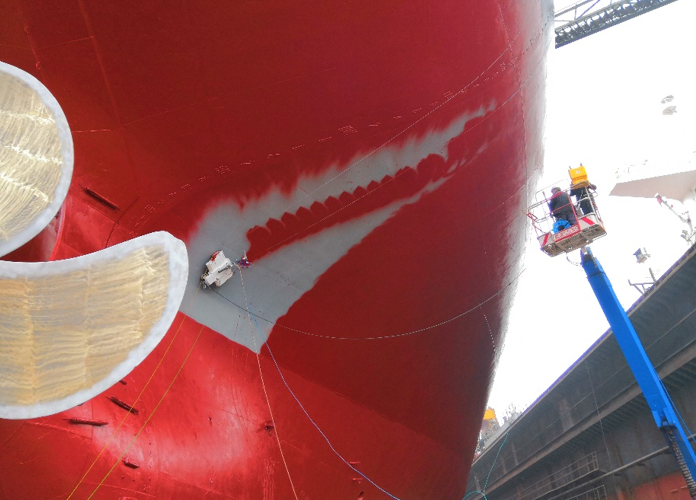

Finally, the team worked hard to carry out the ship painting test.

Huge stern

Robot Spraying

Spraying operation

Finish the task

It took three days for the on-site test. After watching all kinds of robot operations, the leaders of the shipyard expressed their full affirmation of the robot in ship operation and maintenance. At the scene, Shi He's technicians and shipyard's technicians had a heated discussion and fully exchanged opinions. They gave many constructive opinions on how to better combine the robot with the actual operation, which accumulated valuable experience for our subsequent optimization and improvement of the robot.

A scene of heated discussion

This time, the shipyard and the company's technical team worked overtime day and night, because we know that good products must be ground from the site and come after many tests and improvements, rather than staying in the laboratory all the time. Robot + + partners have always been advocating a rigorous and pragmatic work style, just like our mission - let there be no dangerous work in the world! Passionate and simple, but this kind of simple, it is a kind of hard work, a kind of perseverance to do a good product!

I would like to dedicate this article to all robot + + siege lions who contributed to the R & D line in 2018!